Onze disciplines

Reverse Engineering

We use our CAD/CAM department, which works with the TopSolid software package, to engineer parts or to reverse engineer existing parts.

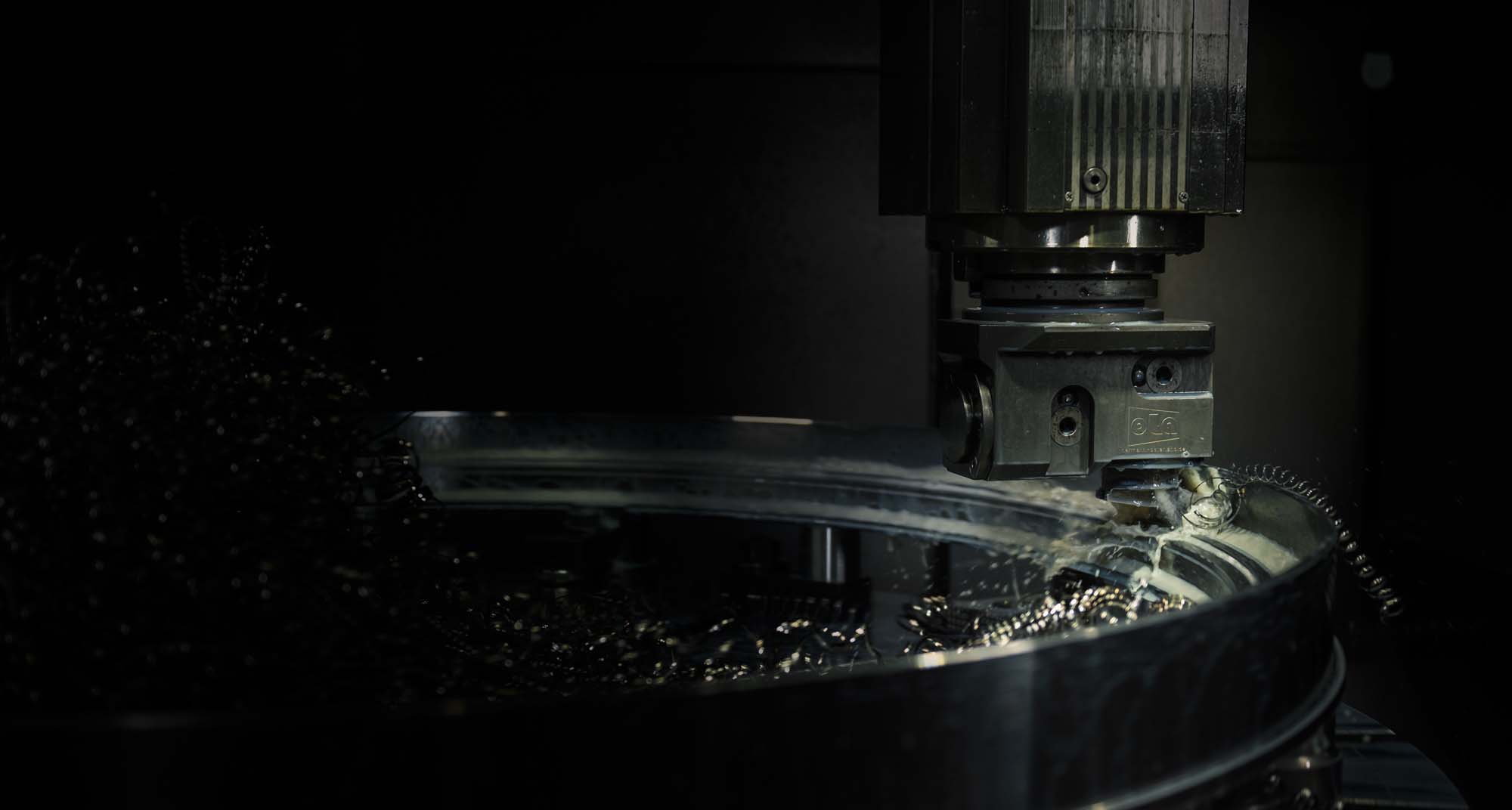

MACHINING MATERIALS

We machine the supplied steel, aluminium, stainless steel and non-ferrous alloys and can also supply the required material, casting mould or forged piece ourselves. We are thoroughly familiar with working with and procuring high-quality materials in accordance with specific requirements and properties. Besides machining metal, we can also deliver and machine certified welded work.

read more

CASTING/ANNEALING

At AFMI, we cast and anneal white metal. This enables us to produce complete white metal bearings.

SURFACE TREATMENTS AND HARDENING

We are also your party of choice if you require surface treatments or hardening. This includes vacuum hardening, nitriding, carburising, anodising, black annealing, galvanising and chroming. Besides manufacturing separate parts, we can also assemble and mount entire assemblies.

QUALITY CONTROL

Before shipping a product to the customer, we perform a quality control using calibrated measuring instruments in accordance with our ISO 9001 certification. This involves checking all tolerated dimensions, threaded holes and fit tolerances and recording the results in a measurement report. We always send this report to the customer to safeguard our quality.

Transport

We are also happy to arrange transport to the customer’s location, as the last step. If desired including special packaging or crates.

Different markets, unparalleled possibilities

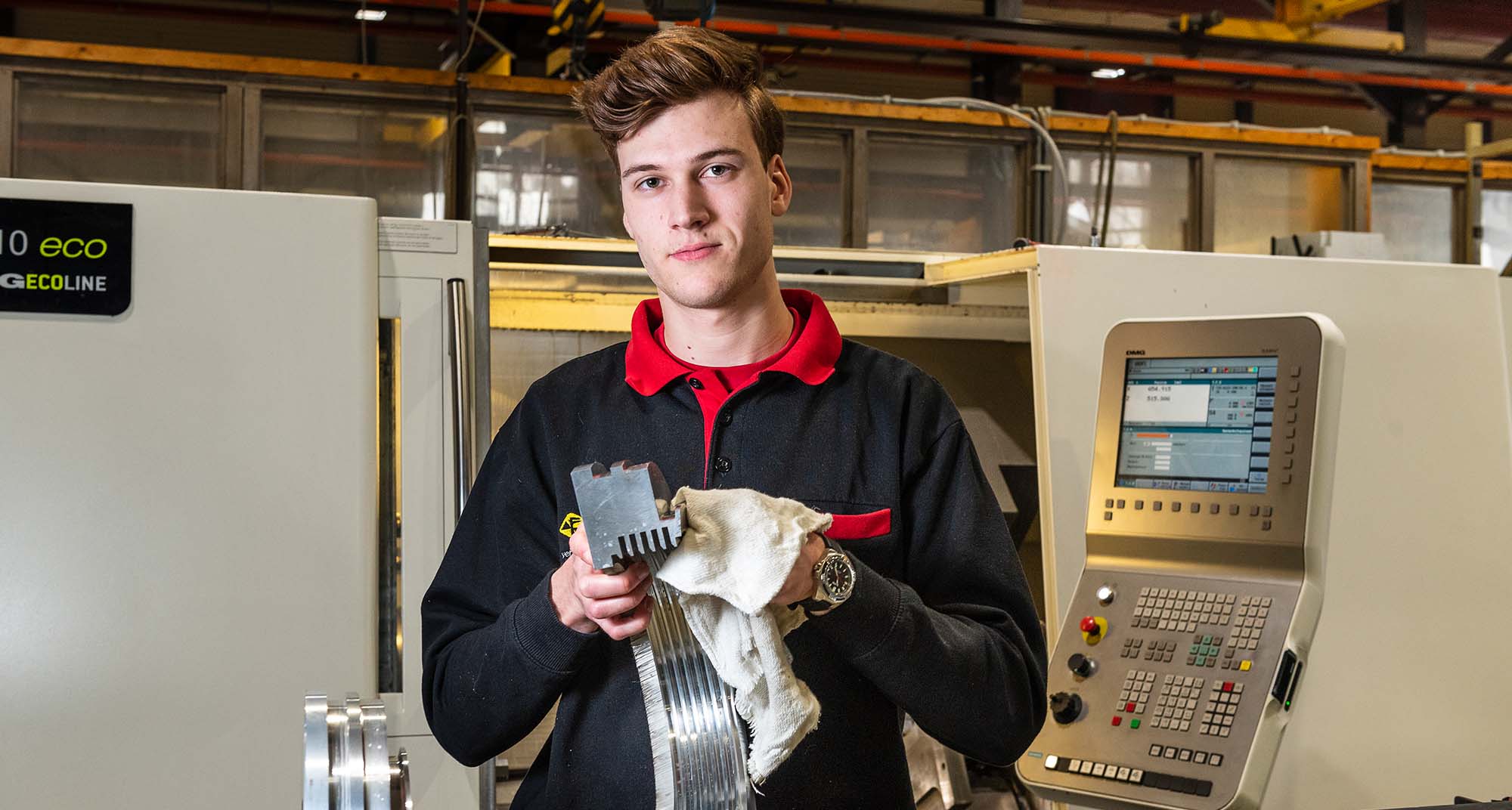

With the right attitude and effort, you can achieve all you want here, and you’ll be given plenty of opportunities to develop as far as possible. After completing my secondary education, I have been able to develop further within AFMI through various training courses.

Corné Muller – CNC Turning operator

AFMI offers me the opportunity to develop myself. In the meantime I am happy to support the 6-axis indexed milling machine and make a wide variety of products here. Whether I program myself or receive programs, every day is full of new challenges.

Robin Boevink – CNC Milling operator

I qualified for all my training certificates and diplomas at AFMI. AFMI is a great company, with many good clients and very varied work, primarily one-offs or limited series, so there’s plenty of variation. There is no shortage of training opportunities, and extra schooling and/or training courses are always possible.

Dennis Batterink – CNC Milling operator

Witmetaal gieten

Bij AFMI zijn we specialist in veel verschillende productietechnieken. Witmetaal gieten is daar één van. Maar hoe gaat dat proces in zijn werk? En wat maakt het zo’n specifieke techniek?…

Read more

Metaaltopper Remco

Metaaltopper van de maand december is Remco Manders. De foto hierboven is een paar weken geleden gemaakt bij een traditionele draaibank, maar inmiddels is hij bij AFMI Verspanende Industrie al…

Read more